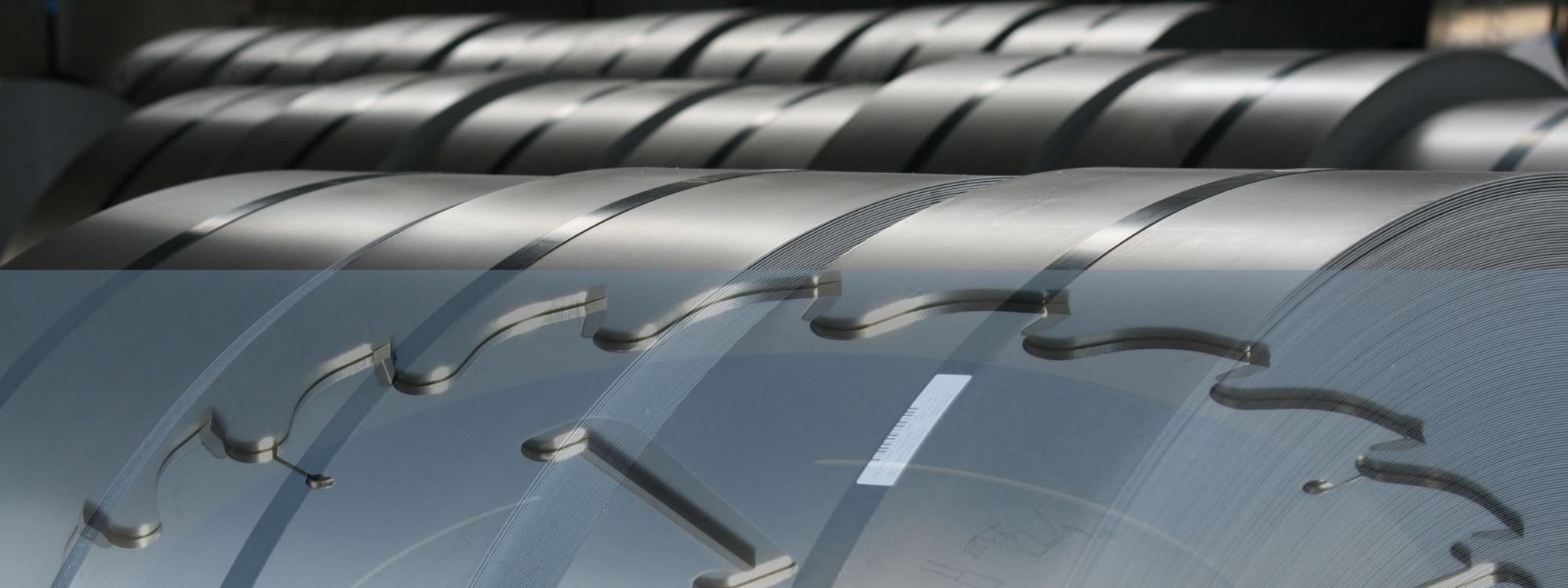

Steel for saws

Our product range includes many grades and dimensions for various applications in the saw steel industry. This covers:

Circular saw blades:

a) Standard grades: C75S, 75Cr1, 80CrV2,

b) Special grades: RiWillit, 75Ni8, 68CrNiMo33, 27MnCrB5-2

Band saws:

a) Standard grades: 51CrV4, D6A, C75S, 75Cr1

b) Special grade: RiWimendelejew

Gang saws for woodworking industry:

a) Standard grades: C75S, 75Cr1, 80CrV2

b) Special grade: 75Ni8

Gang saws for natural stone working industry:

a) Standard grades: C75S, 75Cr1, 75Ni8

b) Special grade: RiWistone

We can also offer additional grades with C-contents from 0,25-1,00%.

For a/m grades please find the characteristics below:

|

Chemical cast analysis |

Chemical analysis based on DIN EN 10132-3+4 and 10083-3 respectively, also special analysis |

|

Strip thicknesses (mm)(1) |

Martensite: 0,30 – 5,10 | Bainite: 0,50 – 4,00 |

|

Strip widths (mm)(1)(3) |

Martensite: 35 – 720 | Bainite: 24 – 650 |

|

Mechanical properties (1) Hardness range / Range of tensile strengths |

Martensite: Spring steels hardness 30 – 54 HRC Tempering steels hardness 30 – 46 HRC Boron-alloyed steels hardness 30 – 44 HRC Bainite: Tempering-/ spring steels Rm = 800 – 1.600 MPa |

|

Surfaces (appearance + finish) |

Bright, grey-blue, blue or yellow tempered, brush-polished, belt-grinded |

|

Edge condition |

GK- slit edges, NK- mill or as-rolled edges, SK- special edges (machined or edge-rolled) |

|

Dimensional tolerances |

General tolerances: acc. to DIN EN 10140 and special agreement Strip width tolerances: acc. to special agreement only |

|

Flatness |

Usually max. 1.0 μm/mm width for martensitic tempered spring steels with C-contents of 0.67 - 1.00 %, max. 1.5 - 2.00 μm/mm width for boron-alloyed grades and tempering steels. For the bainitic condition acc. to special agreement only. |

|

Delivery forms |

Coils and cut lengths |

|

Cut to length dimensions (2) |

Thickness: 0,50 – 5,10 mm Width: 80 – 720 mm Length: 400 – 4.000 mm |

|

Specialities |

Hardening of low carbon steel with very good flatness values. Hardening of extreme cross-sections with especially wide and thick dimensions Hardened into intermediate structure with in-line decarbonisation for special applications |

|

(1) =Variations depending on grade and dimension to be taken into account (2) = Further dimensions upon agreement (3) = Strip width < 35 mm only available in slit-after-hardening condition |

|